Targeted Spray Technology: Companies, Functionality and Benefits

Written by Ricardo Pinto, MSU Extension, June 2025.

Written by Ricardo Pinto, MSU Extension, June 2025.

Precision agriculture continues to revolutionize modern farming, and one of the most significant innovations now available to producers is precision spot spraying technology. Unlike traditional broadcast herbicide applications, spot spraying targets only areas of active weed growth, significantly reducing the volume of chemicals applied while maintaining effective control. This approach has shown particular promise in fallow systems, pastures, and increasingly in row crops, where early weed detection can prevent yield loss and slow the spread of herbicide resistance. Precision spot sprayers use real-time camera imaging and artificial intelligence to distinguish weeds from crops, enabling on-the-go decisions and targeted herbicide applications as the equipment moves through the field.

Advantages of Precision Spot Spraying

The benefits of precision spot spraying are numerous. Most notably, these systems can reduce herbicide use by up to 90%, depending on weed pressure and field conditions. This leads to substantial cost savings, especially in large-scale operations where chemical expenses are a major component of production costs. Beyond economics, spot spraying contributes to environmental sustainability by minimizing herbicide runoff, protecting beneficial soil organisms, and reducing the potential for herbicide resistance due to overapplication. The ability to apply treatments precisely also helps protect non-target plants and reduces the overall ecological footprint of weed control practices. Because most systems can be integrated with existing machinery, the transition to spot spraying can often be made with less disruption than adopting a completely new platform.

Challenges of Precision Spot Spraying

Despite the advantages, there are challenges associated with spot spraying implementation. High upfront costs can be a barrier, particularly for smaller operations, although per‑acre pricing models (as seen in some platforms) are emerging to make access more flexible. Accurate system performance also depends on careful calibration, optimal lighting conditions, and appropriate sensor heights. In dense crop canopies, green‑on‑green detection remains more difficult, and the technology continues to evolve to improve precision under these conditions. Producers using this technology also note that the system’s inherent limitations in detecting all weeds may require an additional pass to achieve satisfactory control. Producers also need to develop familiarity with system software and ensure their teams are trained to manage these digital tools effectively.

In summary, precision spot spraying is an exciting and impactful development in weed management. It supports producers in reducing costs, improving efficiency, and making more sustainable chemical applications. As more companies enter the market and systems become more robust, this technology will likely become a core tool in the precision agriculture toolbox, helping farmers manage increasingly complex production challenges with greater confidence and precision.

What to Consider When Purchasing a Spot Spraying System

When evaluating which precision spot spraying system best fits your operation, several factors should be carefully considered. One of the most important is the system’s detection capability, specifically, whether it can handle both green-on-brown and green-on-green scenarios. Green-on-brown detection is typically effective in fallow fields or bare ground conditions, while green-on-green is essential for in-crop spraying where weeds must be distinguished from the crop canopy. Systems that perform well in both situations offer greater flexibility and season-long value.

Additionally, cost structure is an important consideration. While some platforms are sold as one-time purchases, others operate on a per-acre subscription model, which may appeal to producers seeking to manage upfront investment and ongoing costs differently.

Compatibility with existing equipment, ease of integration, and whether the system supports retrofitting or requires a dedicated sprayer should also factor into the decision. Other critical elements include camera and sensor types, software user interface, the ability to collect and export geospatial data (as applied maps), and the company’s support, training, and service offerings.

Producers are encouraged to evaluate performance under their specific crop and field conditions, as well as the system’s ability to function reliably in variable light, soil, and canopy environments. Ultimately, the most suitable system will align with a producer’s operational goals, technical capacity, and economic thresholds.

Available Precision Spot Spray Systems

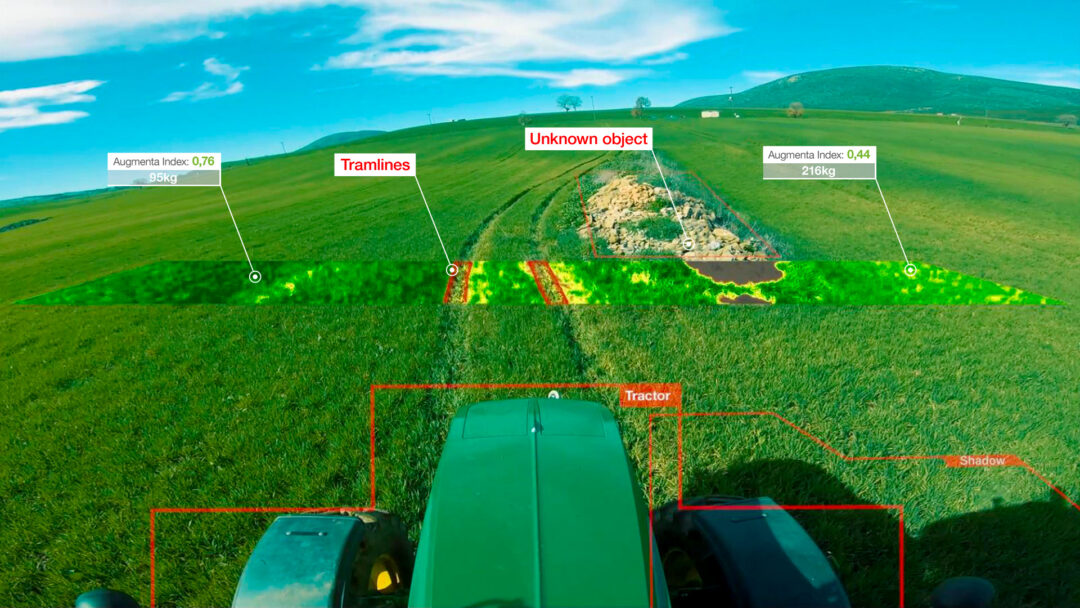

Several commercial systems are currently available and have been adopted by farmers globally. These include John Deere's See & Spray™, Trimble's Bilberry® and WeedSeeker systems, WEED-IT Quadro, Carbon Bee Smart Striker X, the Ecorobotix ARA platform, and CNH Industrial’s Augmenta system. Each platform offers unique features, though most rely on RGB or multispectral/hyperspectral cameras combined with machine learning algorithms to identify vegetation and differentiate between desirable and undesirable plants. Depending on the system, spot spraying units can either be installed as retrofits on existing sprayers or purchased as integrated standalone machines.

In terms of functionality, most systems follow a common process: cameras scan the field in real-time, software processes the visual data to detect weed presence, and solenoid-controlled nozzles activate instantly to deliver a precise spray to the weed target. Some systems, such as Augmenta, are also capable of performing variable-rate fertilization and canopy analysis, making them multifunctional platforms for broader crop management applications. In addition to their weed-killing role, many spot spray technologies collect geospatial data that can be used to inform long-term management strategies and optimize other farming operations.

John Deere See and Spray Systems

See and Spray Select is primarily designed for fallow ground applications, utilizing color detection technology to identify green vegetation on brown soil. This system can achieve significant herbicide savings, averaging around 77% reduction in non-residual, pre-emerge herbicide use. It operates at speeds up to 25 mph (40 kph) and can be retrofitted to existing spraying equipment with an ISOBUS-compatible display. While effective in fallow conditions, See and Spray Select is not intended for in-season use within crops.

See and Spray Premium bridges the gap, offering targeted spraying capabilities for both in-season and fallow field applications. This system, available as a precision upgrade for MY2018 and newer John Deere sprayers, utilizes boom-mounted cameras and machine learning to distinguish crops from weeds. It can achieve over 50% savings on non-residual herbicide costs and operates at speeds up to 12 mph. See and Spray Premium is compatible with various boom sizes and requires existing ExactApply, BoomTrac Pro 2, and a G5 CommandCenter display on the sprayer.

See and Spray Ultimate represents a more advanced solution, capable of in-season weed detection in crops such as corn, soybean, and cotton. This system employs computer vision and machine learning algorithms to differentiate weeds from crop plants. It features a dual-tank configuration, allowing for the simultaneous application of two different herbicides to combat herbicide resistance. See and Spray Ultimate can reduce non-residual herbicide use by more than two-thirds and operates at speeds up to 12 mph. It is exclusively available as a factory-installed option on specific John Deere sprayer models.

While the initial focus was on variable rate application based on biomass health, Augmenta is developing its weed identification capabilities, including green-on-brown spot spraying. The system boasts a wide field of view, up to 138 feet, and can operate at speeds up to 19 mph when using selective spray functions. Augmenta aims to provide a versatile solution for optimizing input application across a wide spectrum of crops.

AGCO Weedseeker and Bilberry

Weedseeker 2, developed by PTx Trimble (a joint venture between Trimble and AGCO), is a green-on-brown spot spray system designed to reduce herbicide use by up to 90% by only spraying weeds detected on bare soil or stubble. It utilizes advanced optics and processing power to detect green plants and trigger individual nozzles. Weedseeker 2 can operate day or night at speeds up to 25 mph (40 kph) and can be retrofitted to existing spraying equipment with ISOBUS compatibility.

Bilberry, now also part of PTx Trimble, provides green-on-green spot spraying capabilities using artificial intelligence to identify various weed species in real-time within a broad range of crops. This system can achieve chemical savings of up to 98% by targeting weeds directly without damaging crops. Bilberry's technology is brand agnostic and compatible with a wide range of sprayers, making it suitable for retrofit installations. It can identify specific weeds like broadleaf weeds in cereals, blue lupins in lupins and canola, and grasses.

This retrofit system is designed to integrate seamlessly with all brands and sizes of commercial sprayers. Greeneye employs 24 high-resolution cameras and 12 graphic processing units to achieve plant-level treatment with a 10-inch nozzle spacing.31 It can operate at speeds up to 15 mph, day and night, and has demonstrated an average reduction of 87% in non-residual herbicide use. Greeneye also offers a dual-line system, allowing for simultaneous broadcast application of residual herbicides and precise spot spraying of non-residual herbicides. Supported crops include corn, soybean, and cotton, with expansion to other crops like canola and cereals in development.

This system combines Bosch's camera sensor technology and software with xarvio's agronomic intelligence to precisely detect weeds in crop rows and apply herbicide only where needed. Trials have shown achievable herbicide volume savings of up to 70%. Supported crops currently include corn, soy, cotton, canola, sunflower, and sugarbeet, with plans to add capabilities for more crops like small grains.

This brand-independent system can be retrofitted to various sprayer types and achieves high hit rates between 95% and 98% with potential herbicide savings of up to 95%. WEED-IT QUADRO can detect weeds as small as 1 cm² at operating speeds up to 16 mph (25 kph) and works day and night. It features four detection zones per sensor and incorporates Pulse Width Modulation (PWM) technology for precise nozzle control. WEED-IT is suitable for broadacre, row crops, and specialty crops.

This system allows for the application of total herbicides exclusively to target surfaces, with potential savings ranging from 20% to 80% compared to full-area treatment. Amaspot is designed for use in stubbles post-harvest or to combat weeds before a new crop emerges.

This system uses RGB color cameras mounted on the boom and employs a self-learning algorithm. AiCPlus aims to provide spot spraying capabilities for both summer spraying (green-on-brown) and in-crop spraying (green-on-green), with trials showing significant chemical reductions. The system can develop algorithms for various weeds visible to the naked eye and has been successfully used for applications like wild radish control in wheat.

This system employs fast and consistent cameras designed for harsh environments and analyzes images in real-time to decide whether to spray. Ecopatch can be adjusted to spray at different thresholds based on the crop selected and field conditions and can be retrofitted to commercially available sprayers with section control and ISOBUS. Initial focus crops include barley and oats, with capabilities for green-on-green and green-on-brown detection.

This retrofit system can achieve herbicide savings between 70% and 90% by automatically opening and closing applicator nozzles in real-time. SprAI uses RGB cameras and artificial intelligence for morphological detection of weeds, even in no-till agriculture conditions. It operates at speeds up to 11 mph (18 km/h) and works day and night with LED lighting.

This solar-powered robot is equipped with a 40ft boom and can cover between 49 and 79 acres (20 and 32 ha) per day. Solix uses eight cameras along the boom to identify weeds and prompt targeted herbicide application, achieving up to 98% reduction in herbicide volume in some trials. It also collects data on crop health and nutrient status and operates autonomously 24/7.

This system utilizes embedded artificial intelligence to control PWM systems for precise application. Smart Striker X maps weeds and application in real-time and is compatible with various PWM systems. It can operate at speeds up to 16 mph (25 km/h) and supports spot spraying, dual-dose application, and modulation based on weed or crop biomass. The system uses RGB and hyperspectral cameras for accurate weed detection in a wide range of crops.

This towed machine uses cameras and Plant-by-Plant AI software to detect and treat plants with a precision of 6x6cm. ARA can treat up to 9.9 acres (4 hectares) per hour, day and night, at a maximum speed of 4.5 mph (7.2 km/h). It is compatible with various crop types and can reduce plant protection product usage by 50% to over 95%. ARA offers both green-on-green and green-on-brown capabilities.

|

System

|

Supported Crops

|

Green-on-Brown*

|

Green-on-Green*

|

Max Speed (mph)

|

Retrofittable

|

Per-Acreage Fee

|

|---|---|---|---|---|---|---|

|

John Deere See & Spray Select

|

Fallow fields (no crops, bare soil)

|

✅

|

❌

|

25

|

✅

|

✅

|

|

John Deere See & Spray Premium

|

Corn, soybean, cotton, cereals

|

✅

|

✅

|

12

|

✅ (MY2018+)

|

✅

|

|

John Deere See & Spray Ultimate

|

Corn, soybean, cotton

|

✅

|

✅

|

12

|

❌ (Factory only)

|

✅

|

|

CNH Augmenta

|

Multispectral

|

✅

|

❌

|

19

|

✅

|

✅

|

|

AGCO WeedSeeker 2

|

Fallow fields (no crops, bare soil)

|

✅

|

❌

|

25

|

✅

|

❌

|

|

AGCO Bilberry

|

Cereals (wheat, barley, oats), lupins, canola, legumes, grasses

|

✅

|

✅

|

15

|

✅

|

✅

|

|

Greeneye

|

Corn, soybean, cotton; in dev: canola, cereals

|

✅

|

✅

|

15

|

✅

|

✅

|

|

Bosch One Smart Spray

|

Corn, soy, cotton, canola, sunflower, sugarbeet; upcoming: small grains

|

✅

|

✅

|

12

|

❌ (Integrated w/ Fendt Rogator)

|

✅

|

|

WEED-IT Quadro

|

Fallow fields (no crops, bare soil)

|

✅

|

❌ "incrop mode"

|

16

|

✅

|

❌

|

|

Amazone Amaspot

|

Fallow fields (no crops, bare soil)

|

✅

|

❌

|

12

|

✅

|

❌

|

|

Agrifac AiCPlus

|

Wheat, summer crops, general row crops

|

✅

|

✅

|

18

|

✅

|

✅

|

|

DAT Ecopatch

|

Barley, oats (initial); others under dev.

|

✅

|

✅

|

Unspecified

|

✅

|

Unknown

|

|

DeepAgro Sprai

|

Soybean, corn

|

✅

|

✅

|

11

|

✅

|

Unknown

|

|

Solinftec Solix

|

Wheat, Corn, Soybean, Cotton, Sugarcane

|

✅

|

✅

|

1 (Autonomous)

|

❌ (robot system)

|

✅ SaaS price service

|

|

Carbon Bee Smart Striker X

|

Wheat, Barley, Potatoes, Sugar Beet, Maize, Grassland, Turf, Carrots, Onions, Beans,

Peas, Oilseed Rape (OSR), Sunflowers

|

✅

|

✅

|

16

|

✅

|

❌

|

|

Ecorobotix ARA

|

Row crops, vegetables, specialty crops (high-value crops), sugarbeet

|

✅

|

✅

|

4.5

|

❌ (Self-contained towed unit)

|

✅

|

* Green-on-brown: refers to the system's ability to detect green plant material (weeds) against a non-vegetated background such as bare soil, crop residue, or stubble, typically during fallow periods or early pre-plant stages. These conditions create a high contrast, making weed detection more straightforward.

* Green-on-green detection represents a more advanced capability: identifying and targeting weeds growing within a green crop canopy. This requires the system to differentiate between crop plants and weeds based on subtle differences in shape, spectral signatures, or spatial patterns, making it a key feature for in-crop spraying applications.

Ricardo Pinto

Assistant Professor

Precision Agriculture Research/Extension