Fermentation process effects on 'McIntosh' apple ciders

A website summary of Fermentation Process Effects on Fermented McIntosh Apple Ciders (https://doi.org/10.3390/fermentation10030115).

by Zhuoyu Wang 1, Andrej Svyantek1,Zachariah Miller1*, and Aude A. Watrelot2

1Western Agriculture Research Center, Montana State University, Corvallis, MT, 59828, USA; zachariah.miller@montana.edu (Z.M.)

2Department of Food Science and Human Nutrition, Iowa State University, Ames, IA 50011, USA

* Author to whom correspondence should be addressed.

Summary

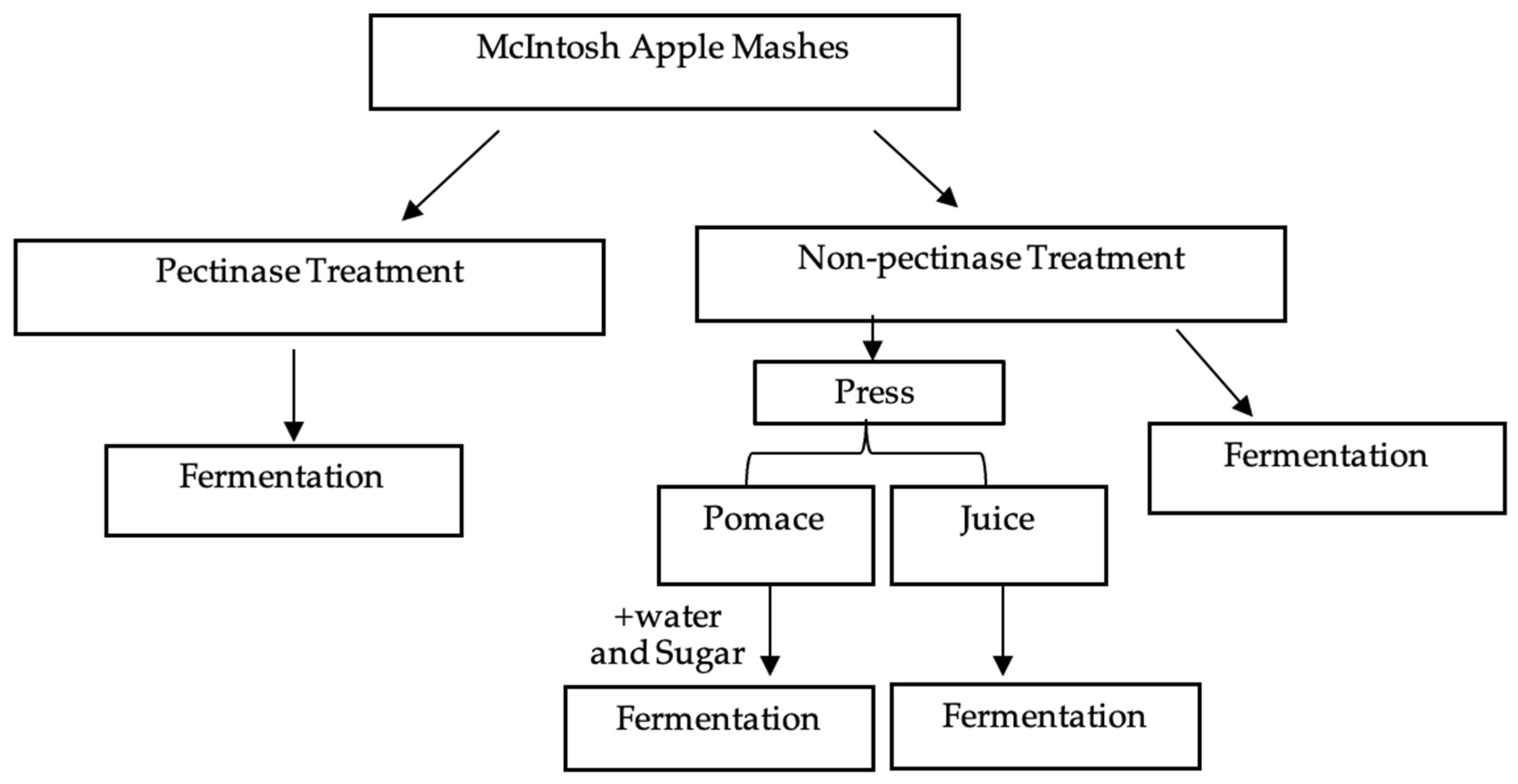

This study investigated how different starting materials—apple juice, mash (crushed apple pulp and skins, fermented with or without pectinase), and pomace (the starting material for ciderkin, but with added sugar to match the alcohol content of standard cider)—affect the fermentation process and final quality of ‘McIntosh’ apple ciders. All three methods successfully produced cider, but each influenced the final product’s color, polyphenol content, and flavor profile in distinct ways:

Juice-based ciders had the highest antioxidant levels but lowest flavonols. Largest color changes.

Mash—both with and without pectinase—produced the most flavonols. Stable color.

Pomace-based ciders retained the least hydroxycinnamates but similar flavanol levels to juice-based ciders. Stable color.

These findings suggest that mash and pomace are cost-effective, sustainable alternatives to juice in cider production, offering opportunities to reduce waste and diversify product offerings.

Introduction

‘McIntosh’ apples are prized for their sweet-tart flavor, aromatic profile, and adaptability to cold climates. While juice is the most common base for cider, this study explored the potential of using mash (with or without pectinase) and pomace—by-products of juice pressing—as alternative fermentation materials. These materials differ in sugar, acidity, and nutrient content, which can influence fermentation behavior and final cider quality. The enzyme pectinase is often used to improve juice yield and clarity and may also affect flavor and antioxidant extraction.

A key focus of this research was on polyphenols—naturally occurring compounds in apples that contribute to flavor, color, and potential health benefits. Among these:

Flavanols (like catechin and epicatechin) are antioxidants that may support heart health and improve blood flow.

Flavonols (such as quercetin) are known for their anti-inflammatory and immune-supporting properties.

Hydroxycinnamates (like chlorogenic acid) may help regulate blood sugar and protect cells from oxidative stress.

These compounds not only influence the sensory qualities of cider—such as taste, color, and mouthfeel—but also enhance its nutritional value. This research aimed to evaluate how different apple materials and treatments affect the extraction and retention of these beneficial compounds during fermentation, ultimately shaping the cider’s composition and character.

‘McIntosh’ apples were harvested from a historic orchard in Corvallis, Montana. About 60 kg of apples were ground into mash and divided into four treatments:

- Pectinase-treated mash

- Untreated mash

- Pressed juice

- Pomace (solids left after pressing)

Each treatment was fermented at room temperature (21–23 °C) for 12 to 19 days using a commercial yeast strain. Sugar was added to the pomace to match the sweetness of the other treatments. After fermentation, ciders were bottled and analyzed for:

- Basic chemistry: sugar (°Brix), pH, acidity, and nitrogen

- Color changes: tracked throughout fermentation

- Final composition: alcohol, glycerol, and acidity

- Health-related compounds: total phenolics, antioxidant activity, and specific phenolics like flavanols and anthocyanins

Figure 1. McIntosh cider fermentation flow chart indicating partitioning of pectinase-treated mash, untreated mash, juice, and pomace.

To get a preliminary estimate of consumer preference, ciders were taste tested by 15 fruit growers and cider makers.

The composition of the apple musts varied by treatment. Juice, mash, and pectinase-treated mash had similar sugar levels, while pomace had significantly less. All treatments had low nitrogen levels, especially pomace, suggesting the need for nutrient, Yeast assimilable nitrogen or YAN in particular, supplementation.

Phenolic content and antioxidant activity were highest in juice and pectinase-treated mash. Pomace, despite its lower mass, still contributed meaningful levels of phenolics and antioxidants. During fermentation, sugar levels dropped steadily, with pomace fermenting the slowest. All treatments reached minimal sugar levels by Day 14.

Cider produced from juice and pectinase-treated mash was light in color. Cider from pomace had a very light brown color, while mash-fermented cider exhibited the darkest coloration after fermentation.

Final ethanol levels were similar across treatments. Pomace ciders had the highest glycerol, enhancing mouthfeel. Juice ciders had the highest acidity, while pectinase treatment increased acidity and brightness without affecting alcohol content.

In terms of monomeric phenolics, mash and pectinase-treated ciders had the most flavanols. Juice and pomace had less, suggesting flavanols remain in the pomace unless extended contact is allowed.

Conclusions

This study demonstrated that the choice of apple material—juice, mash, pectinase-treated mash, or pomace—significantly affects cider quality. Each method offered unique benefits:

- Juice-based ciders had the highest antioxidant activity and acidity.

- Pectinase-treated mash produced the brightest ciders with the most flavanols and flavonols.

- Pomace-based ciders, though low in sugar and nitrogen, retained valuable phenolics and had the highest glycerol content, contributing to a smoother mouthfeel.

- Mash without pectinase yielded darker, more stable ciders with high flavanol content.

- These findings suggest that mash and pomace are not only viable but potentially valuable alternatives to juice in cider production. Their use can help reduce waste, lower production costs, and create diverse cider profiles tailored to consumer preferences.

In preliminary taste testing, the traditional method (juice) of cider production was improved by these alternate methods. The mash with pectinae and juice-based ciders were ranked in overall preference as the best (average rating of 3.6 on a 5-point scale), higher than mash and pomace ciders (3.3 and 2.9 ratings respectively).

Funding Acknowledgement

This research is funded by the Montana Department of Agriculture. Grant No.: 23SC00309.