Food Safety

in Integrated Crop-Livestock Systems

While integrated livestock can potentially diversify farm income and benefit soil health, knowledge of safe and efficient practices isn’t adequately backed up by data. Through conversations and surveys of Montana growers, we’ve realized many would benefit from better access to practical and relevant information on the potential benefits and risks of adding livestock to their crop production.

Risks

Americans experience an estimated 48 million illnesses, 128,000 hospitalizations, and 3,000 deaths due to foodborne disease each year. While it is common to assume that fruits and vegetables are safer than other types of food (like meat and dairy), produce actually accounts for more foodborne illness outbreaks than any other category of food (46%). Because small outbreaks are so much harder to track, we rarely hear about those caused by produce from small farms. Yet while industrial agriculture is the culprit with many foodborne illnesses, small farms can actually pose a higher than expected risk when they don’t have the resources or regulations to harvest, wash, and store produce in a safe way. For example, in 2003, Escherichia coli (E. coli)-tainted spinach from a small farm sickened 16 and killed two consumers in California.

Preventing pathogen contamination begins in the field with safe practices around irrigation, wildlife, and harvesting crews, and is of special importance concerning foods that are generally eaten raw. The fruits and vegetables responsible for the most recorded outbreaks are: lettuce and leafy greens, tomatoes, herbs, green onions, and raspberries. The primary pathogens causing illness from produce are: Norovirus, Salmonella, E. coli 0157, Shigella, and Campylobacter.

While these risks are concerning, we know how to mitigate many of them through production and handling practices. Following official guidelines from the FDA or USDA can help protect consumers from illness and protect your farm from liability. Many farms are not be required to follow the FSMA produce safety rule due to size or sales strategy, and certification in Good Agriculture Practices (GAP) or the National Organic Program (NOP) are voluntary. However, understanding and implementing applicable regulations on your farm is an excellent practice and opens up many retail and wholesale market opportunities.

Produce Safety Resources

- FDA Food Safety and Modernization Act (FSMA)

- FSMA Produce Safety Information

- Good Agriculture Practices (GAP) standards

- Farmers Handbook for GAP

- GAP vs FSMA

- GAP Field operations and harvest checklist

- USDA National Organic Regulations

- FSMA rule on Biological Soil Amendments of Animal Origin (BSAAO)

Research

Both the FDA and USDA are actively seeking more data to back their recommendations and regulations around Biological Soil Amendments of Animal Origin (BSAAO). Organic production is on the rise, now covering over 5.4 million acres in the US alone, and manure provides an essential source of fertilizer for many of these acres. However, currently available research provides inadequate evidence for how to mitigate risks when using BSAAOs on crops generally eaten raw. In the FDA’s 2013 version of FSMA, the Produce Safety Rule mandated a nine-month (270 day) interval between the application of raw manure (and other untreated BSAAOs) and the crop harvest. Following widespread protest from producers, the FDA deferred action on defining an application interval until further research had been completed. Updates to the Produce Safety Rule in 2016 broadly require that producers apply raw manure in a way that avoids contact with produce and that the irrigation method implemented minimizes the potential for contact after application. In terms of the safe interval between manure application and harvest, the Rule simply recommends that farmers comply with the USDA’s National Organic Program standards* for the time being.

Integrated livestock systems have been the backbone for sustainable production since the dawn of human agriculture. Integrated livestock transform the waste products from crop production into food and fiber, provide invaluable weed and pest management services, and recycle their own waste into soil to feed more crops. Their quality of life in an integrated system can be far superior to the industrial alternative, and they can manage weeds and pests while saving a farm’s labor and fuel inputs. We need integrated livestock systems, so we need better data on how to manage them safely. How much do weather conditions, soil quality, surface coverage, and irrigation methods affect the persistence of pathogens following manure application? This project is working to fill in some of those gaps for Montana producers and help guide informed decision making to maximize farm productivity while minimizing food safety and liability risks.

*ORGANIC STANDARDS: If the crop's edible portion does not contact the soil, the raw manure must be applied 90 days or more before harvest. If the crop's edible portion is below ground (or has direct contact with the soil or soil particles), the raw manure must be applied 120 days or more before harvest. Crops for animal consumption or fiber are exempt.

Table 1. Pathogen Tests Run in 2019

| Test | Test Code | Recommended Procedure |

| E. coli (generic) enumeration (2 mL for petrifilm) | EC-PETRI | Lab Director will determine the # of dilutions. |

| Campylobacter (30 mL) | CAMP-ELFA | Remove 30 ML of rinsate. Add 30 ML 2X Bolton-blood free + supplement (following USDA carcass rinse enrichment). |

| Listeria monocytogenes (25 mL) | LM-ELFAIDU (this code adds a USDA confirmation) | Remove 25 ML of rinsate. Enrich in 225 ML Demi-Fraser with secondary transfer to Fraser. Run on VIDAS LMO2. Update reported units to PER-RINSE. |

| The remaining rinsate and booties are used for the dual ("tri") enrichment (O157, STEC, Salmonella). This will be about 45 ML. | To the remaining rinsate & booties (about 45 ML), add 225 mL mTSB (following USDA environmental enrichment of 'mTSB at 1:6 dilution, incubate at 42C 15-24h'). Run on BAX. | |

| E. coli O157 | ECBXRT-ENV (ECUSDA-CNF for the confirmation if needed | Update reported method reference to USDA MLG, 5, update reported units to PER-RINSE. |

| STECs | STEC-BX-E (this code adds confirmation screen for panels - STECBAXPNL) | Update reported method reference to USDA MLG, 5, update reported units to PER-RINSE. |

| Salmonella | SALMO-APCR (this code adds an AOAC confirmation) | Update reported method reference to USDA MLG 4, update reported units to PER-RINSE, change media to mTSB. Remove prep instructions. |

Foodborne pathogens of concern

- E. coli O157:H7 (most dangerous)

- Salmonella spp (most common)

- Listeria spp.

- Campylobacter spp.

The EC-Petri test is used to measure Enterobacteriaceae, a large family of Gram-negative bacteria including intestinal pathogens such as Salmonella spp, Shigella spp., and E. coli which can cause a wide range of illnesses. This test is widely used in the food processing industry as an indicator of hygiene and food safety. The practice of detecting and enumerating all glucose-fermenting gram-negative rods (Enterobacteriaceae, not just coliforms) has become more common in the food industry, especially in European countries. It is thought that the detection of a wider, better-defined group of organisms, such as Enterobacteriaceae, rather than that of a more limited group like the coliforms, will provide a more thorough assessment of food safety.

Test samples were collected from the orchard using sterilized boot covers to mimic pathogen transfer from an

orchard floor to fruit in the harvest process. Five samples were taken from study

plots between 7 and 114 days after manure application (poultry presence), and three

samples were taken from control plots with no livestock or manure.

Test samples were collected from the orchard using sterilized boot covers to mimic pathogen transfer from an

orchard floor to fruit in the harvest process. Five samples were taken from study

plots between 7 and 114 days after manure application (poultry presence), and three

samples were taken from control plots with no livestock or manure.

ALL Salmonella, Listeria, and Campylobactertests came back negative, despite the high level of test sensitivity.

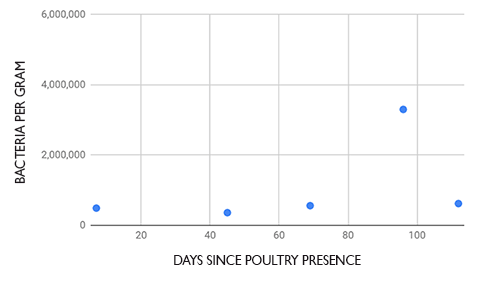

Table 2. Enterobacteriaceae testing

(results varied widely but showed no usable trends)

|

Sample Name |

Days since Lvstk |

Enterobacteriaceae |

|

Mature Orchard 1 (poultry) |

112 |

620,000/g |

|

Mature Orchard 2 (poultry) |

96 |

3300,000/g |

|

Mature Orchard 3 (control) |

N/A |

5900,000/g |

|

N Apple 1 (poultry) |

69 |

560,000/g |

|

N Apple 2 (Poultry) |

45 |

360,000/g |

|

N Apple 3 (poultry) |

7 |

490,000/g |

|

N Apple 4 (control/compost) |

N/A |

160,000/g |

|

N Apple 5 (control/fertilizer) |

N/A |

390,000/g |

Graph 1. Enterobacteriaceae Counts vs Days Since Poultry Presence

Adaptations for 2020

We will be concentrating all of our funding on testing Enterobacteriaceae and will only test in the North Apple orchard system for consistency, with the hope that more samples will allow us to see trends.